Precision Ventilation in Cleanroom Air Flowmeter Systems

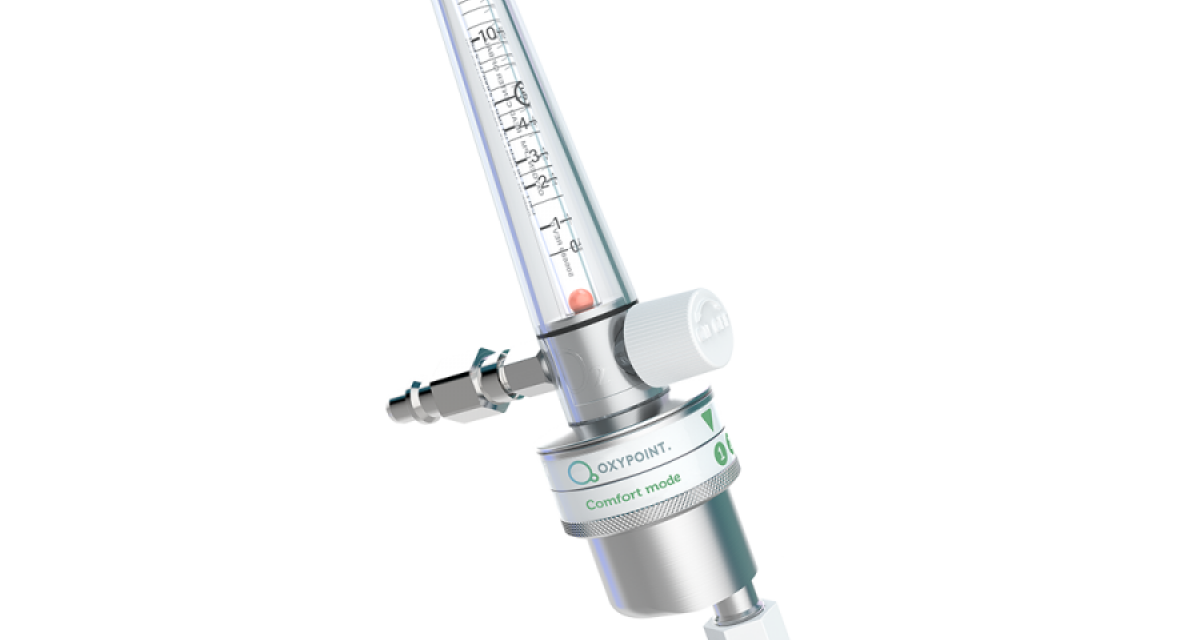

In the realm of cleanroom environments, where maintaining stringent air quality standards is imperative, precision ventilation stands as a cornerstone in ensuring optimal conditions for sensitive processes such as semiconductor manufacturing, pharmaceutical production, and biotechnology research. At the heart of this meticulous control lies the critical role played by advanced air flowmeter systems. These systems are instrumental in regulating the airflow within cleanrooms, where even the slightest deviation from specified conditions can compromise the integrity of the controlled environment. Cleanrooms demand an unparalleled level of precision in air quality control, with factors like particulate levels, temperature, and humidity needing meticulous management. Air flowmeter systems, equipped with cutting-edge technology, are designed to address these challenges by providing accurate and real-time measurements of air velocity and volume. This precision is crucial in preventing the introduction of contaminants, ensuring that the cleanroom environment meets the stringent standards required for the production of sensitive electronic components, pharmaceuticals, and other critical products.

The effectiveness of air flowmeter systems in cleanroom environments lies in their ability to offer not only accurate measurements but also the adaptability to varying conditions. These systems can be strategically placed to monitor and control airflow patterns, ensuring uniform distribution throughout the cleanroom space. This not only prevents localized contamination but also promotes consistent environmental conditions across the entire facility, safeguarding the integrity of the manufacturing or research processes. Moreover, the integration of advanced air flowmeter systems contributes to energy efficiency and cost-effectiveness. By precisely regulating airflow, these systems optimize the operation of ventilation systems, minimizing energy consumption while maintaining the required air quality standards. This not only aligns with sustainability goals but also results in reduced operational costs over the long term. In cleanrooms where processes are highly sensitive to fluctuations in environmental conditions, the real-time monitoring capabilities of air flowmeter systems become invaluable. These systems can detect and respond to changes in airflow patterns promptly, allowing for swift adjustments to prevent potential deviations in air quality.

This proactive approach minimizes the risk of product defects, ensuring the reliability and consistency of the manufacturing or research outcomes and shop air flowmeters at wt farley. Furthermore, the data generated by air flowmeter systems can be leveraged for continuous improvement and compliance purposes. By analyzing historical airflow data, cleanroom operators can identify trends, troubleshoot potential issues, and implement preventive measures. This data-driven approach not only enhances the reliability of cleanroom operations but also facilitates compliance with industry regulations and quality standards. In conclusion, precision ventilation is paramount in cleanroom environments, and the critical role of air flowmeter systems cannot be overstated. These advanced systems provide the accuracy, adaptability, and real-time monitoring capabilities essential for maintaining the stringent air quality standards required in industries where even the slightest contamination can have profound consequences. By ensuring optimal conditions through precision ventilation, air flowmeter systems contribute to the reliability, efficiency, and long-term sustainability of cleanroom operations.